Cookie

This website requires cookies to provide all of its features. For more information on what data is contained in the cookies, please see our Privacy Policy page. To accept cookies from this site, please click the Accept button below.

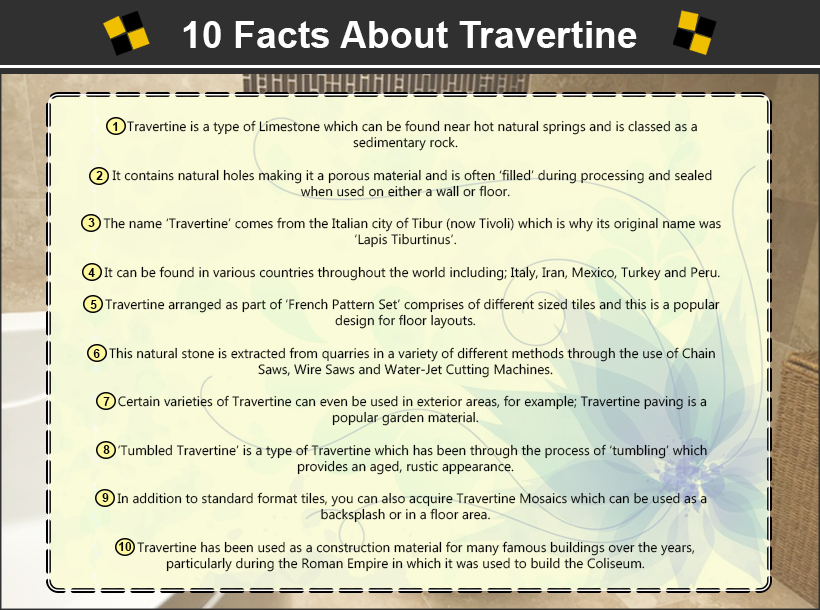

Natural Travertine tiles are sought after for a wide range of projects. Travertine is a type of Limestone and they are both formed in close proximity to hot natural springs. Travertine is notable for having light pastel colours like cream, ivory and grey. This natural stone may also contain skeletal fragments of living organisms which can be seen on the surface of tile in the form of fossils. These tiles have a unique character which has made them a popular choice for a wide variety of home designs. Below we are not only going to be taking a look at the ways in which Travertine tiles can be used as part of home designs but also its formation process and the how it can be cleaned and maintained.

With its soft neutral colours and unique natural features, it is no surprise that Travertine tiles are often acquired for modern bathrooms. They work particularly well with contemporary bathroom fittings and applications. As part of a bathroom interior, Travertine tiles are used in various ways including as a standard wall and floor covering but also as mosaics in shower areas and as bath surrounds. Travertine is selected for wet rooms, en suites and larger bathroom layouts. Due to its predominately soft beige and cream shades Travertine matches extremely well with other colours and features. Now we are going to take a closer look at the more specific ways in which Travertine can be used in a bathroom.

A shower area not only requires a stylish appearance but also a covering that will protect the underlying substrate from moisture damage. Travertine works superbly as part of shower designs and can be used on either the wall or floor. On walls, large format Travertine tiles can be used to make smaller shower areas appear bigger in size. The reduced amount of grout lines through the use of larger tiles creates an uncluttered look which is why they are well suited to shower enclosures and produce a spacious appearance. Bathroom shower area floors need to have an increased level of slip resistance and that is why Travertine Mosaic tiles are often selected for this part of the room; the increased grout lines provide a greater level of friction opposed to a flat large surface. Matt Travertine Mosaic tiles can be used in the area which directly surrounds the drain. Mosaics are flexible because they are attached to mesh sheets which mean the can be applied to sloping floors in wet rooms.

The versatility of travertine means it can be used on both the front of a bath, where a bath panel would normally be, and also as the backsplash wall surround. For a minimalist style, a niche bathroom wall is a great way of providing additional space and works particularly well with Travertine. The neutral quality of Travertine is of particular value in modern bathrooms as you can change applications including baths, sinks, shower screens and taps and handles over time but you may not decide to replace the tiles providing they have been well maintained. For a consistent appearance, you can even chose to match a bath surround with the Travertine tiles on a floor. A matching design can be effective in accentuating the available space. You may however, choose to contrast Travertine wall surround with porcelain or granite on a floor.

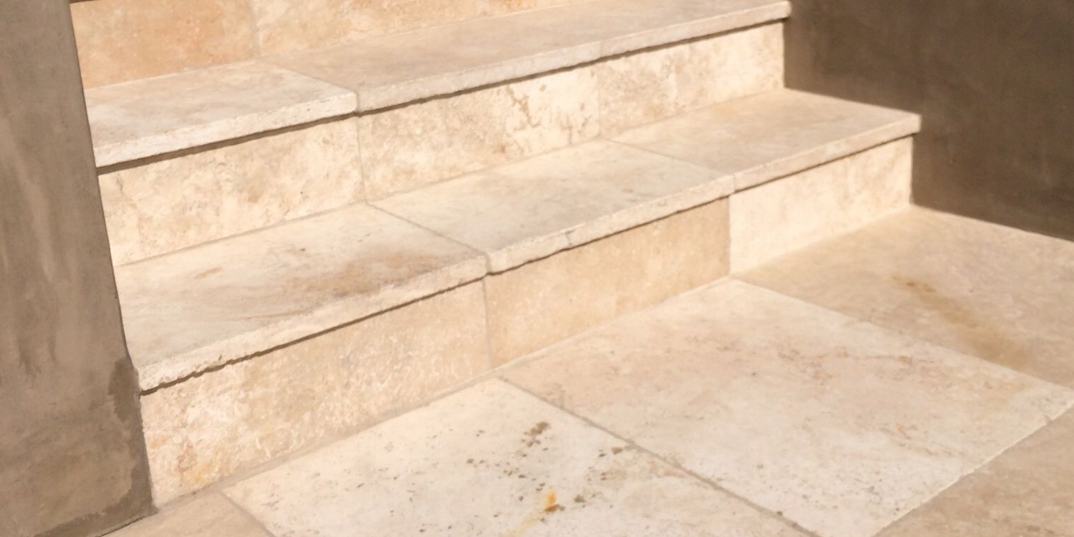

When it comes to choosing Travertine tiles for a bathroom floor, honed and matt varieties are often preferred. These tiles have a non-gloss finish and provide a greater level of slip resistance than polished surfaces. On bathroom floors, rectangular Travertine tiles can be displayed in a brick style (running bond formation) which adds genuine character to bathroom interiors. Using a lighter coloured grout can offer a subtle contrast too and will emphasise the pattern further. As aforementioned, mosaics are an excellent option for the area which directly surrounds the drain in a wet room. If you have steps which lead to a raised bathtub then Travertine is also an outstanding option for this.

Wet Rooms are a good use of the available space, particularly when it comes to smaller en suite bathrooms. Traditionally, wet rooms do not have baths or shower trays and this provides a streamlined interior which is also easier to maintain. Wet rooms require a sloping floor design for the water to drain away effectively from the area. Specific products like Wedi Boards are often used in this process. The soft, neutral appearance of Travertine certainly provides wet rooms with a fresh and invigorating style. The natural beauty of Travertine can be accentuated further in wet rooms by artificial lighting on ceilings, with spotlights proving especially effective for this. In terms of the wet room design itself, you can use standard format, square or rectangular Travertine Tiles on the wall, and apply mosaics in the area which surrounds the drain. Mosaics are attached to flexible mesh sheets which makes them perfect for a sloping floor in this area. Travertine mosaics with a honed, matt finish are ideal for this particular situation.

There are various ways in which Travertine can be incorporated within kitchen designs. This versatile natural stone is well suited to a vast array of kitchen layouts. Kitchens are busy parts of the home and the good thing about Travertine is that it will not only transform kitchens from an aesthetic perspective but also has the required durability. With its cream and beige colours, Travertine is superb for providing any interior with a neutral backdrop.

In general, Travertine is possibly most notable for its use as a bathroom tile. This, however, doesn’t mean that it is not also an excellent choice for kitchens. As a kitchen floor tile, Travertine in a rectangular format can be arranged in a running bond style which will really accentuate its natural character. Honed, matt Travertine is particularly well suited to kitchen floor layouts and can be complemented by a vast array of unit, cupboard and worktop styles. Whether you have a standard kitchen or one which also incorporates a dining area, the versatility of Travertine tiles is certainly of great importance in this part of the home.

Travertine is capable of transforming your kitchen design as part of a backsplash, which is the area between your worktop and oven hob and the units above. Standard format Travertine tiles can be used for this but mosaics are probably better suited as they can be applied to smaller areas with ease. For that classic farmhouse style, combining Travertine tiles with wooden kitchen units and worktops is a popular technique. In modern kitchen interiors, Travertine can be matched with plain cupboard doors and also black granite worktops. Travertine is such a versatile material that it can be matched with virtually any other application.

Many people have conservatories which they enjoy relaxing in, particularly during the warmer months. A conservatory can prove to be quite a high traffic area as it is a natural walkway from the interior to the exterior of your home and vice versa. For this reason it requires a hardwearing floor covering which can withstand the demands of people walking in outdoor footwear, the presence of potentially heavy furniture and general wear and tear. Limestone tiles are therefore an outstanding choice for conservatory floors. Limestone floor design will complement a traditional half bricked conservatory wall. A sought after option for modern interior conservatory walls are Brick Slips as they are lightweight and can be applied to a range of wall substrates. You could also choose limestone for your conservatory walls too with the light, soft colours offering a shimmering glow with the bountiful natural sunlight these areas are exposed to. If you have chosen limestone for your conservatory floor then for a consistent theme you may want to select limestone for other floor areas throughout your home.

Travertine is mostly recognised as a cream and beige colour. There are different variations of this shade and travertine tiles are marketed accordingly. Although the process of calibration and a specific finish being applied can produce a more uniformed look, travertine is still a natural stone, meaning each tile will be completely unique. This means that travertine from the same batch can vary. Usually though, these variations are quite subtle. This natural character is what makes travertine tiles such a sought after choice for walls and floors. The variations are a result of the mineral content within travertine. In its pure form travertine is actually white as it is a type of calcium carbonate. Minerals will alter this colour dramatically which is why it is commonly found in a cream or beige colour. We thought it would be a good idea to explain the variations of cream and beige travertine tiles available:v

Light travertine tiles have a subtle pastel shade, with cream being the predominant colour. There is usually the inclusion of a darker beige colour as well. Travertine has a distinctive pattern which is a consequence of the layers of sediment which have built up during the formation process. Most travertine tiles have been cross-cut which creates a swirly, flowery-like pattern. Light travertine tiles can be so pale in colour that they are described as ivory cream or ivory beige. The elegance of light travertine tiles makes them a popular option for bathrooms where they are combined with equally subtle colours and features.

Unsurprisingly medium travertine tiles have a shade which is in between that of light and dark. This is generally a traditional beige colour. Medium is possibly the most popular colour category of travertine when it comes to interior designs. Medium travertine tiles tend to comprise of a standard beige colour and darker brown shades. Medium and light travertine tiles are often combined in what is known as multi travertine tiles. A good example of medium beige travertine tiles are the Travertino Romano from Italy. These Romano tiles are sourced from the outskirts of Italy’s capital Rome.

Dark travertine is a dark beige and brown colour. This travertine is often called Walnut Travertine such is its distinctive brown colour. It can also feature lighter cream veins and patches. Dark travertine tiles are regularly chosen for outdoor paving. The dark colour conceals dirt and dust extremely well. Dark travertine also suits the rustic style of a French Pattern set layout or brick effect formation. For interior areas dark travertine often has a highly polished finish, in contrast to light and medium travertine which tends to have a matt surface. Highly polished dark or walnut travertine is regularly contrasted with white grout lines.

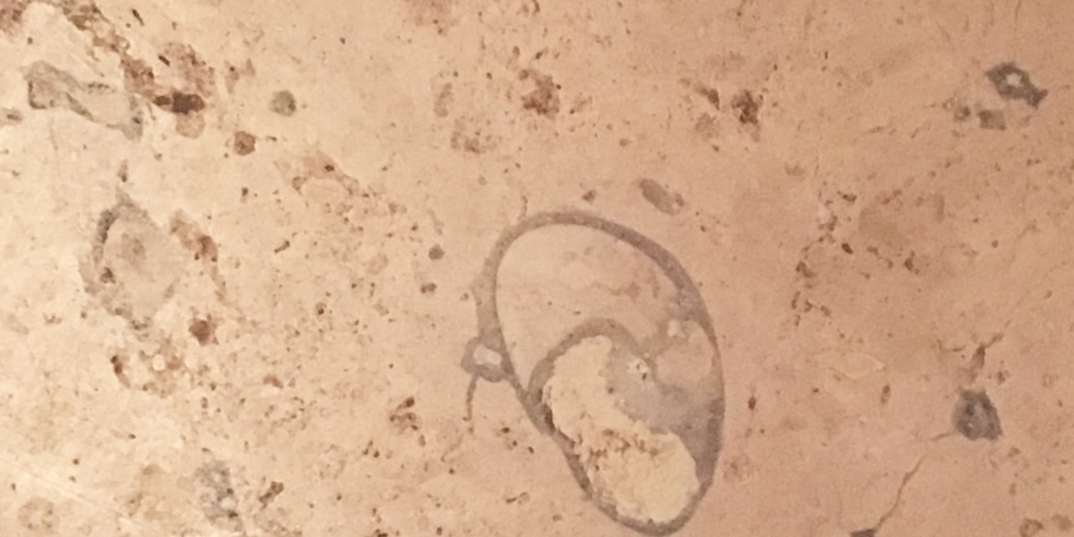

As a result of its formation, limestone has naturally occurring fossils which are the remnants of marine organisms. These fossils are likely to be millions of years old and are therefore perfect if you are looking to introduce a truly unique character in a bathroom or kitchen. Fossiliferous limestone can often contain fossils which are microscopic in size and cannot be seen by the naked eye. The macroscopic fossils within limestone are the ones we can visibly see on the surface of these natural stone tiles. These fossils are often the remains of hard shelled mollusks. Instead of arranging fossil tiles next to each other on a floor or wall, tiling contractors often space these tiles out in order to provide a consistent layout.

Travertine sometimes has a stronger colour than the pale shades of cream and beige. This can manifest into a bright yellow or orange shade. These bright colours are particularly prevalent in areas in which a high mineral content can be found. Yellow and orange travertine is often chosen for paving in outdoor areas. Tile retailers sometimes market polished yellow travertine as gold. This is gold colour has much to do with the finish itself which creates a glossy appearance. Possibly the best example of yellow travertine in the world is found in the Yellowstone National Park in USA. The name actually derives from the large amount of yellow travertine deposits which define the landscape throughout Yellowstone. Travertine waterfalls and mountain ranges are a spectacular sight to behold for visitors to the Yellowstone area.

Grey travertine tiles are available in both lighter and darker shades. Grey is considered an excellent choice for refined and sophisticated designs. For a more emphatic appearance grey travertine is polished and marketed as a ‘silver’ colour. Grey travertine is prevalent throughout many regions of Iran. Mahallat in Iran, is an area in which grey travertine is extracted in large quantities each year. Grey travertine was regularly used as a construction material. The stone is still evident in many towns and cities throughout the world as exterior facades and decorative features. It also appears as paving slabs and steps.

Travertine rock builds up in layers of several different elements through the process of calcium carbonate precipitation. Minerals along with other naturally occurring organisms like plant life and skeletal fragments of small creatures will often be part of this process. The extent of the minerals can determine the colour. A high mineral content can produce a dark brown shade. Brown travertine is often described as ‘walnut’ or dark beige. Brown travertine can feature lighter cream and beige veins. These veins are particularly noticeable when the stone has been vein cut for use as wall and floor tiles.

In certain regions throughout the world travertine has a vibrant red colour. The best example of red travertine is seen in the Mazandaran Province of Northern Iran. In the Badab-e Surt area in particular, red travertine terraces dominate the landscape. Badab-e Surt actually translates to gassed water, which is in reference to the hot natural springs in the region. The red coloured stone is a result of the iron carbonate content within the travertine. Pure travertine usually forms from calcium carbonate which is a white colour. The iron carbonate, however, has a red colour and this appears in the travertine stone. Red travertine is often highly polished in order to accentuate this bright red shade. Rock quarries are present in the Mazandaran Province from which red travertine is extracted and transported in containers to countries throughout the world.

Although, it is also applied to other natural stone tiles the French Pattern Set is most associated with travertine. This pattern comprises of irregular shapes and sizes which all fit as part of the same format. The French pattern set is also known as the Versailles pattern. It is a popular choice for rustic floor designs in both interior and exterior areas. In keeping with this rustic style, travertine in a French pattern set normally has a brushed and unfilled finish. To emphasise this pattern, grout lines tend to be wider than average and of a different colour, usually white or ivory when the stone is brown or beige.

The classic farmhouse style kitchen appearance is one which many homeowners strive for. Despite having a generally traditional character it can also incorporate contemporary features. Natural materials or at least engineered products with a natural style are the most obvious choices for farmhouse style kitchens. Travertine tiles on floors laid in a French pattern can be complemented by wooden units and worktops.

Conservatories are a transitional room from interior to exterior areas. Travertine as a material is extremely well suited to a conservatory design as it can work equally well in either application. Travertine in a French pattern laid on a conservatory floor has proven to be an excellent choice in many modern conservatories. Travertine paving in outdoor patios and driveways can also be applied in this way.

Travertine can be bought within a set of individual pieces, which require installation in order to create the French Pattern. If you have had no previous experience with tiling then it is recommended you acquire the services of a tiling professional for this job. The arrangement can be quite complicated as standard Versailles patterns comprise of four different shapes. It is particularly important to mark out your floor thoroughly before tiling and also remembering to take grout lines in to consideration.

Within the home travertine can not only be used effectively as a wall or floor tile but also for a range of other purposes. When extracted from quarries in large blocks travertine is cut and moulded for its intended use. Travertine has proven to be a versatile material for decorative reasons in home interiors, with the items made from this stone also being of practical significance. It is a relatively soft stone which means decorative features and patterns can be carved into its surface to display a distinctive appearance.

Often standard travertine wall tiles are used for fireplaces but specialist applications require particular cuts of stone. A full travertine fireplace will comprise of a base, back splash panel, mantelpiece and decoratively carved panels either side of the fire itself. Beige and cream are colours which feature in a lot of home living rooms. Travertine, with its pastel shades will fit perfectly as part of interiors with a strong neutral element. Natural stones like travertine have also proven to be a practical option for fireplace surrounds as they are less likely to melt or become discoloured like certain engineered products. Unfilled travertine with a tumbled finish is often chosen for fireplaces.

Travertine specified for worktop applications tends to be filled with a resin filler to provide this porous stone with a high level of resilience. Travertine contains air pockets which actually makes it lighter and therefore easier to fit than other stone based worktops. Bespoke travertine worktops can also be shaped and moulded to fit in with the style of your kitchen. This may include a rounded edge to create an inward curve for a breakfast bar. It is important for travertine worktops to be sealed for protection against stains and moisture damage. Travertine worktops often have a high polish making them easier to clean.

For added protection at the foot of walls, skirting boards are applied throughout homes. In most cases a travertine skirting board is chosen to complement a travertine floor although it can also be used as a one off feature. Stone skirting boards made from sedimentary rocks like travertine are generally more durable than standard wooden skirting boards. Travertine skirting boards are also seen in restaurants and shops in which a high level of foot traffic requires a strong and durable material.

Travertine stone is made into various forms of tables including coffee tables, dining tables and table-tops as part of garden furniture sets. Depending on their intended use the cut and finish applied can vary. For interior areas, travertine table tops are usually honed, filled and polished. Interior travertine tables have usually been cross-cut meaning the stone is cut along the bedding lines to reveal a flowery pattern, which is why it is also described as ‘fleuri’ cut. Vein cut travertine displays the natural vein formation within this sedimentary rock. Travertine tables with a vein cut are preferred for exterior furnishings.

As a stone which can be sculpted and carved with relative ease, travertine is regularly used for making fountains and garden ornaments. Its formation near and within hot natural springs seems to give it a particular suitability as far as water is concerned. Decorative travertine fountains and ornaments provide gardens with a stylish focal point. It is not only in residential garden areas where travertine fountains are displayed but also in the grounds of hotels and leisure centres. Fountain designers are often inspired by the travertine terraces within the Pamukkale area of Northern Turkey where water runs down through springs, creating a sight of extreme natural beauty. Further examples of how water is synonymous with travertine can be seen in the waterfall in the Yellowstone National Park in America, which cascades over travertine rock.

Travertine tiles are honed through a process of grinding. The naturally uneven surface of travertine is ground down with machinery. The actual process involves the surface of the travertine being rubbed with an abrasive like silicon or carbide. A constant supply of water will help to control the high level of dust produced during the honing process. Tiles can be honed by hand but the majority are provided this finish with machinery. This produces a smooth, yet gloss free finish. Honed travertine is also marketed by stone retail outlets as ‘matt’ and has a high level of slip resistance on floors. A honed surface is the most popular travertine finish for interior designs. Honing can change the appearance of travertine as it reveals previously unexposed air pockets. Crevices are sometimes filled with a resin to make the stone more resilient.

Honed and filled travertine is regularly chosen for bathroom and kitchen walls, floors and countertops. Honed travertine tiles are often butted up close to each other for a seamless finish. ‘Filler’ is usually added to the stone before it is honed and is left to set before the honing process takes place. This filler is usually a liquid resin which is poured into the natural holes and crevices, therefore making the stone less porous. This resin hardens, providing a similar composition to that of the stone itself.

Tumbled travertine tiles have a highly rustic and rugged appearance. The process of tumbling takes place when the travertine is placed in a large tank of water and abrasives. As the name suggests the travertine tile is then ‘tumbled’ within the tank. Tumbling produces a weathered appearance, creating a scuffed surface and unfilled holes. Tumbled travertine is also known as having an ‘antique finish.’ The edges of the travertine tile also become chipped, further adding to a rugged look. Tumbled, chipped edge travertine is popular for rustic designs. To make the stone less porous and more durable the travertine is often filled with a resin. Tumbled travertine tiles with a chipped edge are a popular choice for farmhouse style kitchens. These kitchen designs with a rustic character often comprise of other natural materials like stone and wood. Tumbled travertine with a chipped edge is also used as outdoor paving in gardens. To accentuate the rustic character tumbled travertine is usually tiled in a running bond, brick effect style. Tumbled travertine may also be marketed as travertine with a rock finish. Tumbled travertine is considered to be the closest thing possible to this sedimentary rock in its natural environment.

Travertine is polished for a sleek appearance, created by extensive grinding. A travertine tile with a polished finish can have a very different look to that of the natural material. Colours are accentuated, for example a grey travertine tile can have a metallic look when it has been highly polished. Even subtle cream and beige colours are emphasised by a highly polished finish. Polished travertine tiles are also filled with a resin mixture for a uniformed appearance. Stone retail outlets often market travertine with a high polish as a silver colour. To create a polished finish travertine tiles are grounded down under immense pressure, producing a high shine. In keeping with this sleek look the edges of the tiles are straight and the tiles have an even thickness. A term for this is calibrated. For a streamlined look these tiles can be placed on floors with extremely thin grout lines, creating a seamless design. As a result of polished tiles being extremely sleek and shiny they can be easily cleaned. Dust and dirt can simply be wiped from the surface of polished tiles in most cases.

Unfilled travertine with a honed finish is often brushed and chiselled to create a rustic look. The surface of the travertine stone is mechanically brushed to provide a slight texture making it suitable for indoor and outdoor situations. The edges are often chiselled for additional character, producing an authentic feel. This is a particularly popular finish in cream, beige and brown travertine tiles. The subtle variations in shade create a distinctive style, matched with a natural effect finish.

Travertine forms from the chemical compound calcium carbonate. It is deposited from water in mineral springs, particularly hot springs or streams containing a high level of calcium carbonate. The calcium carbonate begins as a jelly substance before hardening and turning into the porous stone, travertine. Travertine is classed as a terrestrial sedimentary rock created as a result of the precipitation of calcium carbonate. Calcium carbonate is made up of a range of elements including; Skeletal fragments of marine organisms, snails, coal balls, pearls and egg shells. The skeletal fragments of marine organisms will form as fossils within the travertine. When travertine is cut open after being extracted from the ground these fossils are revealed. Travertine is a form of limestone and is created in or near to a natural source of water. The formation process itself is quite complicated. Water, rich in carbon-dioxide, dissolves limestone and becomes saturated with it. The water will then resurface with the sudden drop in pressure and change in temperature causing the water to release a carbon-dioxide gas. The calcium carbonate will then re-crystallise to form porous travertine rock. This process is called rapid precipitation. Tufa is a sedimentary rock which forms in a similar way, although it is more common in water of ambient temperature.

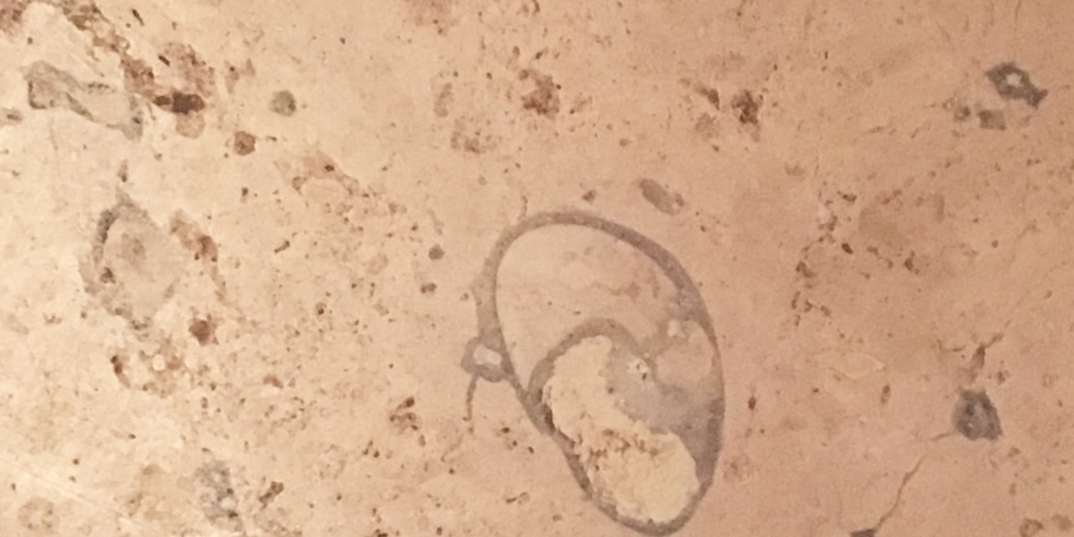

Travertine is a porous stone which builds up in layers of sediment over millions of years. Travertine forms near hot natural springs from a chemical compound called calcium carbonate. One of the components of calcium carbonate is the skeletal fragments of marine organisms. These remain as fossils when calcium carbonate precipitates and turns into travertine. Fossils are therefore regularly found within travertine itself. As a result of travertine forming close to natural water supplies the majority of fossils found within this sedimentary rock are that of small marine creatures. Other fossils that have been discovered are that of plant life, particularly coral which grows in water. Fossils occur in most sedimentary rocks like travertine and limestone. Fossils are less likely to be discovered within igneous and metamorphic rock. Unlike these types, sedimentary rocks are not formed at a temperature which will destroy the remnants of a fossil. Usually when people refer to fossil tiles they will be most likely talking about travertine or limestone.

It is still quite rare to find fossils in travertine so when they are discovered they are invariably considered to be of particular decorative value. Many designers believe that the appearance of fossils adds character to wall and floor designs. Travertine fossil tiles are therefore much sought after for both residential and commercial projects. Within a batch of standard travertine tiles there might be a small number which contain fossils. Some batches contain solely travertine with fossils on them which are often called multi fossil tiles. With the pastel shades of travertine, fossils of a darker colour stand out considerably, therefore providing a decorative feature. The fossils are usually relatively small. It is uncommon to find fossils of large animals or plant life which has remained intact for millions of years. The appearance of fossils can be accentuated by the way in which the travertine stone has been cut. Travertine with a fleuri cut tends to show the best examples of fossils within this natural stone. A high polish or honed finish will then help to emphasise the fossil appearance further.

Travertine is recognised as both a practical and decorative material, therefore making it much sought after for staircases and swimming pools. Travertine stone is used as a staircase cladding and swimming pool material in a range of different ways. Travertine staircases and stone clad swimming pools are most prevalent within commercial properties. There is, however, also a relatively high demand from the residential market.

Travertine staircases are a regular feature within many hotels and shopping centres. The steps can be made from travertine panels or alternatively, the staircase structure is covered in travertine tiles. Travertine is a relatively soft natural stone and can be easily carved for decorative purposes meaning spiral staircases are a viable option when it comes to natural stone travertine. Travertine complements other natural features like wood particularly well. This is why travertine is often matched with a wooden banister. Travertine stone which has been filled with resin based ‘filler’ provides a hard wearing and durable surface. This means that travertine can be applied to staircases in which there is often a high level of foot traffic. Staircase finishes tend to be of a matt variety, which provides a high level of slip resistance. Polished staircases are also available in a range of colours. When a major hotel or shopping centre refit is being undertaken then a large quantity of materials are required. Certainly for commercial projects in the UK, the travertine is imported from countries like Italy, Spain or Turkey. Architects will often choose natural stone like travertine as a staircase material. The natural appearance and dense nature of this stone makes it highly suitable. Travertine has been used as a construction material for thousands of years and was used in some quite famous staircases. For example the staircase which leads to the Aztec Pyramid at St. Cecilia Acatitlan, Mexico is made from travertine stone.

Maybe it’s the inception of travertine in hot natural springs which prompts many designers and architects to choose it as a material for swimming pools. Travertine mosaics are regularly used for both the interior and surround of a swimming pool or Jacuzzi. This suitability for swimming pools means that travertine is regularly chosen for health spas and leisure clubs, not just in swimming pools but also throughout the interior itself, including saunas and steam rooms. Travertine is also used in one off swimming pools in villas, hotels and apartments. Travertine with a matt, honed finish is the safest choice for swimming pool surrounds. A tumbled finish can create a natural, rock-pool appearance in swimming pools, a design which is often seen in themed water parks. Travertine in a French pattern is applied as patios which surround outdoor swimming pools. The inner pool itself is sometimes tiled with ceramic or porcelain, with the outer areas provided by a travertine surface for a stylish contrast.

The concept of small individual pieces of tile being combined together to form a pattern on a wall or floor was first devised by the Ancient Romans. This mosaic style of decoration was used in famous Roman bath houses. Many spectacular murals were created with the use of different coloured mosaics. Since those days, where each individual piece would be laid as part of a design, mosaics have changed quite dramatically. Travertine mosaics are now available in flexible mesh sheets which allows for easier, more consistent tiling. There are also engineered mosaics on the market although natural stone varieties such as travertine have a closer resemblance to the original design. This is because originally, the mosaics would have been used from carved pieces of rock and stone, quite often travertine itself.

Travertine mosaic tiles are available in a range of different patterns. The shapes of the individual mosaics tend to be a standard square or rectangle. The way they are formatted onto the mesh sheets can have a big impact on the design itself. These mesh sheets can be cut easily to form borders and splash backs. Below we take a look at the various patterns of travertine mosaics available:

The stacked bond is the most common type of travertine mosaic pattern. This pattern comprises of individual square mosaics in a standard grid formation. Sizes can vary from a multitude of small square mosaics to fewer but larger squares. They can be available in one standard colour for example; light beige travertine mosaics and also a mixture of two or even a multitude of shades, which are marketed as mixed travertine mosaics.

This is travertine stone which has been cut into a Rhomboid Diamond shape and arranged on to a mesh sheet. This travertine diamond pattern is regularly used as a splash back above worktops in kitchens. In larger formats it can be used on floors, particularly in bathroom shower areas.

A brick effect style is most common with rectangle travertine mosaics. When tiled as a splash back it gives the impression of a brick wall, yet in a trendy, smaller format. This stylish pattern often comprises of different colours most regularly cream, beige and ivory.

A hopscotch pattern is when square mosaics are tiled in a slight diagonal pattern. The small gaps between the tiles are filled with smaller stone mosaics. The combination of sizes within this travertine mosaic pattern creates a visual contrast.

Rectangular travertine mosaics of the same size are formatted as part of a Herringbone pattern. This mosaic pattern creates a highly decorative style. Creating this pattern yourself with individual travertine tiles can prove quite difficult. Travertine Herringbone mosaics are attached to mesh sheets meaning the pattern is already in place and it just simply requires attaching to a wall or floor with grout and adhesive.

Windmill travertine mosaics comprise of a mixture of rectangular and square shapes. The pattern gives the appearance of a small square mosaic with a larger rectangular border surrounding it. This combination of geometric travertine shapes provides a simple yet effective design on walls and floors.

Travertine rectangular mosaics formatted in differing styles to create contrasting square patterns, making a basket-weave appearance. Basket-weave tiles often have a matt, tumbled finish for added rustic character.

A Plaza pattern travertine mosaic comprises of a mixture of sizes, shapes and colours. With its random pattern, the plaza style displays a genuinely rustic quality.

Mini French pattern set travertine mosaics are a smaller version of the popular style often seen on kitchen floors. The pattern tends to include a variety of shapes and colours, therefore providing a high rustic quality. A French pattern set is also known as a Versailles pattern.

Travertine has been used within the construction industry for thousands of years. Despite its porous nature, travertine is a tough and durable sedimentary rock making it ideal for structural projects. Travertine stone has been used to construct many famous buildings throughout the centuries. In modern day construction projects, travertine tends to be chosen as part of a decorative facade. Travertine is extracted from quarries in large blocks. Travertine intended for construction is cut into brick format or large slabs. Travertine wall cladding is used in both interior and exterior designs. Travertine is used within both residential and commercial building projects.

Travertine stone has been used to construct famous buildings throughout the world. The Coliseum in Rome was once the largest building in the world. This stunning amphitheatre was built in the City of Rome, Italy between 70 and 80 AD. It is possibly most famous for being the scene of gladiatorial contests and is still a major tourist attraction to this day. A huge travertine facade surrounds the Coliseum and this natural stone also clad the terraces within the arena itself. The Coliseum now stands partially ruined as a result of earthquakes and stone robbers. It was a common theme to use travertine in the construction of large buildings. This may be a result of its plentiful supply in Europe from countries such as Italy and Spain. Travertine was used to build the Burghausen in Germany, which still remains as Europe’s largest castle. Travertine has also been used throughout the 20th and 21st centuries within modernist architecture. Examples of this are seen in the modernist Willis Tower in Chicago, formerly known as the Sears Tower. When the tower was built in 1973 it was the tallest building in the world. The Getty Centre in Los Angeles, California which opened in 1997 is renowned for its stunning architecture. The Getty centre was constructed mainly of travertine stone and comprises of a museum and research institute.

Travertine is a relatively soft stone making it easy to carve in the creation of decorative features. Travertine has been carved and sculpted to create impressive statues and features. Henry Moore was a famous English sculptor and artist. Moore used stone and bronze in many of his sculpture. A famous Moore sculpture; ‘The Arch’ in Kensington Gardens stands at six metres tall and is made from Roman Travertine stone. It is light grey in colour and is positioned in a great vantage point for Kensington Place itself. The smooth texture on the outside of ‘The Arch’ suggests that the surface of the stone has been heavily grounded down or honed. A honed surface is achieved with heavy machinery and provides a smooth yet non reflective finish.

Travertine contains natural holes and voids as a result of its formation process. Layers of sediment build up and crevices can be left by vegetation which becomes trapped between these layers. This makes travertine a porous stone and therefore not the first material people think of when it comes to construction. Impermeable resin also known as ‘filler’ is poured into these holes to make it suitable for use in construction. This process, therefore, makes travertine highly suitable for exterior projects. With all the air pockets within the stone being filled the stone is less likely to become damaged as a result of contraction and expansion due to freezing. Filled travertine has been used as a paving material in many cities throughout the world.

The ever growing self-build market in the UK has resulted in an increased demand for natural stone materials like travertine. More and more people are buying their own plot of land on which they construct their brand new home. As proven by travertine’s extensive used in modernist architecture, it works particularly well in contemporary homes and buildings. Travertine complements large glass windows which have been a popular inclusion in many self-build homes. Importing travertine from countries like Italy and Turkey is not as expensive as many homeowners are led to believe. Travertine is transported to the UK in large containers. For the construction of self-build properties large cuts of travertine are used as an exterior facade and outdoor patio.

Travertine is a natural stone and is therefore generally heavier than engineered tiles like porcelain and ceramic. Using the correct grouts and adhesives to ensure the tiles are securely fixed to wall and floor surfaces is therefore imperative for safety reasons. Making sure the grouts and adhesives are applied correctly is also very important. Below we take a look at the options available to you when it comes to fixing travertine tiles to a wall or floor. We also take a look at the correct methods of applying the grouts and adhesives.

Certain adhesives are only suitable for specific areas when it comes to fixing travertine tiles. When fixed correctly, travertine tiles can last for a very long time in both interior and exterior areas. We provide some guidelines on the types of adhesives which can be used when tiling with travertine.

Ready mixed tile adhesives are usually available in a plastic tub container. They have a paste like consistency and are ready to be applied straight onto a substrate without adding water. It must be noted however that ready mixed tile adhesives are not suitable for fixing travertine tiles in all circumstances. Ready mixed adhesives should only be used on internal walls and floors and dry or intermittently wet areas. There are two separate grades of ready mixed tile adhesives which are D1 and D2. It is important to read the instructions thoroughly before using ready mixed tile adhesives. The majority of ready mixed tile adhesives can be used when fixing travertine but this should certainly be clarified before carrying out the job.

Cement based tile adhesives are generally considered to be the most suitable variety when fixing natural stone travertine tiles to walls and floors. Most types of cement based tile adhesives are suitable for interior and exterior use. They are also highly resilient to moisture, making them more suitable than ready mixed adhesives when tiling in bathrooms, outdoor patios and even swimming pools and Jacuzzis. Cement based adhesives are a dry powder sold in bags. They need to be mixed with water, with the correct amount being stated on the packaging. Most tiling contractors will use cement based tile adhesives for fixing travertine tiles. Not only are they are considered to be a more efficient adhesive but they are also cost effective, especially when purchased in bulk. There are two varieties of cement based adhesives to look out for; which are standard set and rapid set. Standard set usually sets in around 24 hours whereas travertine tiles installed with rapid set may be ready to grout within a few hours. Elastomeric tile adhesive is a variety of cement based adhesive. This adhesive is said to withstand vibration. It is, however not regularly used with travertine but is instead a more common option for securing timber floors.

An even layer of adhesive should be spread across the surface of the wall or floor to ensure there are no gaps between the back of the travertine tile and the underlying substrate. Gaps can create weak points and will therefore make the travertine tiles more prone to cracks and breakages. This is why dot and dab fixing, in which only a small amount of adhesive is used to securely attach the tile, should be avoided on all occasions. The adhesive spreader can be used to create ridges which will provide extra adhesion when laying tiles.

Choosing the variety of grout can depend on the type of travertine finish and also where the travertine is being installed. For standard travertine tiles, un-sanded grout is the best option. Some grouts contain sand which may scratch the surface of the travertine tile. Just like adhesive, you have two main options when it comes to grout; ready mix and dry powder. Once again the dry powder which you mix yourself is most suitable for travertine tiles. Probably the biggest decision you will face when choosing your grout is the colour. Waterproof grouts are preferred when travertine tiles are concerned. Unlike adhesive, the grout lines will be visible so it is therefore important to establish what will work best with the travertine tiles you are installing on your wall or floor. The traditional cream and beige colours of travertine are usually combined with a white or ivory grout. This is particularly useful when emphasising a specific pattern, for example a herringbone or French Pattern Set. This look tends to be achieved with wide grout lines, which are regularly seen in rustic designs.

Travertine is a porous stone and despite a lot of tiles having a resin filler to make them more impermeable they still require sealing. After fixing your tiles you should leave the adhesive to set thoroughly. Before you apply the gout a lot of tiling professionals will recommend sealing the tiles first. This will ensure that the grout does not ‘bleed’ into the tiles causing a stain. It is important that the sealant has dried completely before grouting takes place. Another coat of sealant can be applied once the grout has dried.

Travertine is a sedimentary rock which is extracted from the ground in huge blocks, often weighing as much as 50 tonnes. There are two common types of travertine cuts, and these are a vein cut and a fleuri cut. Each of these cuts has a different effect on the appearance of the stone. Travertine is cut in factories with an industrial stone cutter. Travertine forms in layers of sediment and therefore veins are exposed when the stone is cut. Fossils of small marine animals can also be found within the travertine. Below we take a look at these two cuts, which are made whilst the stone is being prepared for the retail market

When travertine is vein cut the blade cuts against the bedding planes. This cut really accentuates the veined pattern created by the separate layers within travertine. The style this cut creates is often described as a linear pattern. It has to be a certain type of travertine for a vein cut to be effective as otherwise it can leave black lines and a dirty appearance. Vein cut travertine is popular for exterior walls. Because the stone is cut against the bedding planes less holes and air pockets are created on the surface in comparison to other cuts.

In the case of travertine with a fleuri cut the stone is cut along its natural bedding planes. This is also referred to a cross cut. The fleuri cut produces a flowery and sometimes circular pattern across the surface of the travertine. In Turkey this style of cutting is often called American cut. A fleuri cut very often reveals holes and air pockets. These holes are usually filled in with a filler material. This ‘filler’ decreases the level of porosity within the stone making them a suitable wall and floor tile.

Despite being a hard wearing natural stone, travertine tiles can become damaged and broken just like any other wall or floor covering. To save on time and money you can replace the broken tile yourself. When purchasing any tiles you should always remember to acquire a few spares just in case breakages do occur. It is also recommended that you keep some of the original grout cement to ensure the replacement matches the floor or wall design as accurately as possible. Below we explain a method in which travertine can be replaced both quickly and safely.

To remove the travertine, drill holes into the middle of the tile. You can prevent the drill from slipping by applying a strip of tape to the surface of the tile. Make sure you don’t drill all the way through the tile as you could damage the underlying substrate. By using a chisel and hammer you can then remove sections of the broken travertine tile. With a chisel and knife you can then remove the grout and adhesive from this section of the wall or floor. You must then make sure all the small pieces of debris are completely removed. Cleaning this section will also help the adhesive to stick to the surface of the substrate thoroughly. Be careful not damage or scratch surrounding tiles whilst removing the broken one.

Spread an even layer of adhesive in the space left by the travertine tile which has just been removed. You will have to adjust the tile to make sure the surface is level with surrounding tiles. This can be determined accurately with a spirit level. Leave the adhesive to set fully and make sure nobody walks on this section of travertine flooring whilst it is setting. Use tile spacers to create even gaps on each side of the travertine tile. Once the adhesive is set remove the tile spacers and use grout to fill in the joints. This can be achieved with a grout float. Remove excess grout from tiles with a wet cloth. Allow the grout to set for the recommended time before walking upon the tile. You may then wish to clean your travertine tiles before sealing them with an impregnating sealer.

Natural stone travertine requires a certain level of maintenance in the form of cleaning and sealing. The extent and regularity of the maintenance can be determined by the area in which the travertine has been installed. For example, high traffic areas like bathrooms and kitchens may need to be cleaned and sealed on a regular basis. Shower areas and splash backs above worktops are particularly prone to spillages and will possibly need additional treatment in comparison to other parts of the room.

Like all wall and floor materials, travertine requires a certain amount of regular cleaning and maintenance. You may also need to clean certain areas on occasions when stains or marks appear. It is important not to use acidic based cleaners on travertine as these may stain the surface of the natural stone. In general cleaning the tiles should be swept with a soft brush to remove excess dirt and dust. The surface of the travertine can then be cleaned with a mixture of warm water and a neutral cleaning detergent. A mop on floors and a wet cloth on walls can be used to clean the surfaces. The majority of travertine for interior use has a honed, matt finish. This type of finish provides a high level of slip resistance but is, however, more prone to harbouring dirt and dust in comparison to polished surfaces.

If your travertine does have a polished finish this high gloss appearance can become faded over time. When fading does occur the surface of the travertine can be re-polished. You can re-polish your tiles as part of a DIY project. The tiles should be sanded down with sandpaper, used in a circular motion. The technique is to start by using a 400-grit sandpaper, moving on to 600-grit then finishing off with 800-grit. You then use a buffing pad to create the smooth shiny finish, restoring your polished tiles back to their original appearance.

Travertine is a porous natural stone and despite the fact it tends to be filled and honed in preparation for walls and floors it still requires sealing. Protecting the tile with an impregnating sealer will help to prevent stains and in particular damage caused by moisture from occurring. When applied correctly the sealer should create a protective layer, helping to prevent stains from penetrating the surface of the travertine. It is not just travertine tiles which require sealing but also worktops and other home features like skirting boards. Sealants are usually applied to a travertine surface with a paint roller. It is important that the travertine surface has been cleaned and dried first before applying sealant. It is important to read the sealant packaging thoroughly to make sure it is suitable for natural stone. On a newly laid travertine floor the surface is often sealed twice. The first coat of sealant is applied after the tiles are fixed with adhesive. This is then allowed to dry before the gaps between the tiles are filled in with grout. The grout should then be dried and the surface cleaned before another coat of sealant is applied. This method of sealing should prevent the grout from ‘bleeding’ into the travertine tiles, causing dark patches.

The distinctive appearance of travertine has been imitated in the form of manmade tiles. Travertine effect porcelain and ceramic may look similar to the real thing but they have all the practical advantages of an engineered product. Travertine effect tiles can also be a cost effective alternative to genuine natural stone. The majority of travertine effect tiles are available in beige and cream colours. These pastel shades are much used in home bathroom and kitchen interiors as they complement other neutral colours like white and ivory extremely well.

Porcelain and ceramic tiles make up the majority of travertine effect varieties. It is not hard to see why the cost of genuine travertine is generally higher than that of manufactured travertine effect tiles. Natural travertine has to be extracted from the ground with the use of heavy machinery, requiring a large workforce. It then needs to be processed to make it suitable for wall and floor applications. The stone is then cut in factories and the porous holes are filled with a resin based product, with much of the work requiring a skilled workforce. Tiles intended for interior use need to be ‘calibrated’ which means they are cut to a standard thickness. A specific finish is then given to the travertine stone, with the most common being; honed, polished or tumbled. Another cost which needs to be taken into consideration is transportation, with tiles on large pallets often being taken across several countries to reach their destination. Tile retail outlets like tilestravertine.co.uk have ensured that imported travertine tiles can be acquired at affordable prices. The majority of porcelain and ceramic tiles are mass produced meaning they can be sold at low prices. Many homeowners still pay that little bit extra for genuine travertine, however, as they believe nothing can compare to the distinctive character of this natural stone.

The range of finishes and colours available with porcelain and ceramic tiles is endless. A glaze is applied to ceramic and porcelain tiles at the end of the manufacturing process. This glaze provides the tiles with the desired appearance. For a travertine effect, cream and beige shades are the most obvious combination. High quality imitations display the subtlety of this combination as well as the veins and features which are prevalent on many travertine varieties. To complete the travertine look the tiles are usually given a textured finish. A subtle texture is created in the form of a matt glaze. For a more rugged appearance a rock effect finish is applied.

As an engineered product ceramic and porcelain tiles have a few advantages over natural stone varieties. The low moisture absorption rate of ceramic and porcelain tiles makes them ideal for kitchen and bathroom interiors. Natural stone travertine is porous and therefore requires sealing to provide an impermeable surface. Once sealed though, travertine is an excellent wall and floor covering in homes. In general travertine effect porcelain and ceramic tiles do not require sealing, therefore saving you time and money in the long run.

Natural stone is generally heavier than engineered tiles. Ceramic and porcelain are therefore easier to work with. In general a manual tile cutter will be sufficient in cutting ceramic tiles. In the case of porcelain and travertine a more expensive electric wet cutter may be needed. Porcelain and ceramic are usually stored in manageable boxes meaning you can usually acquire these tiles for your project as soon as you are ready to tile.